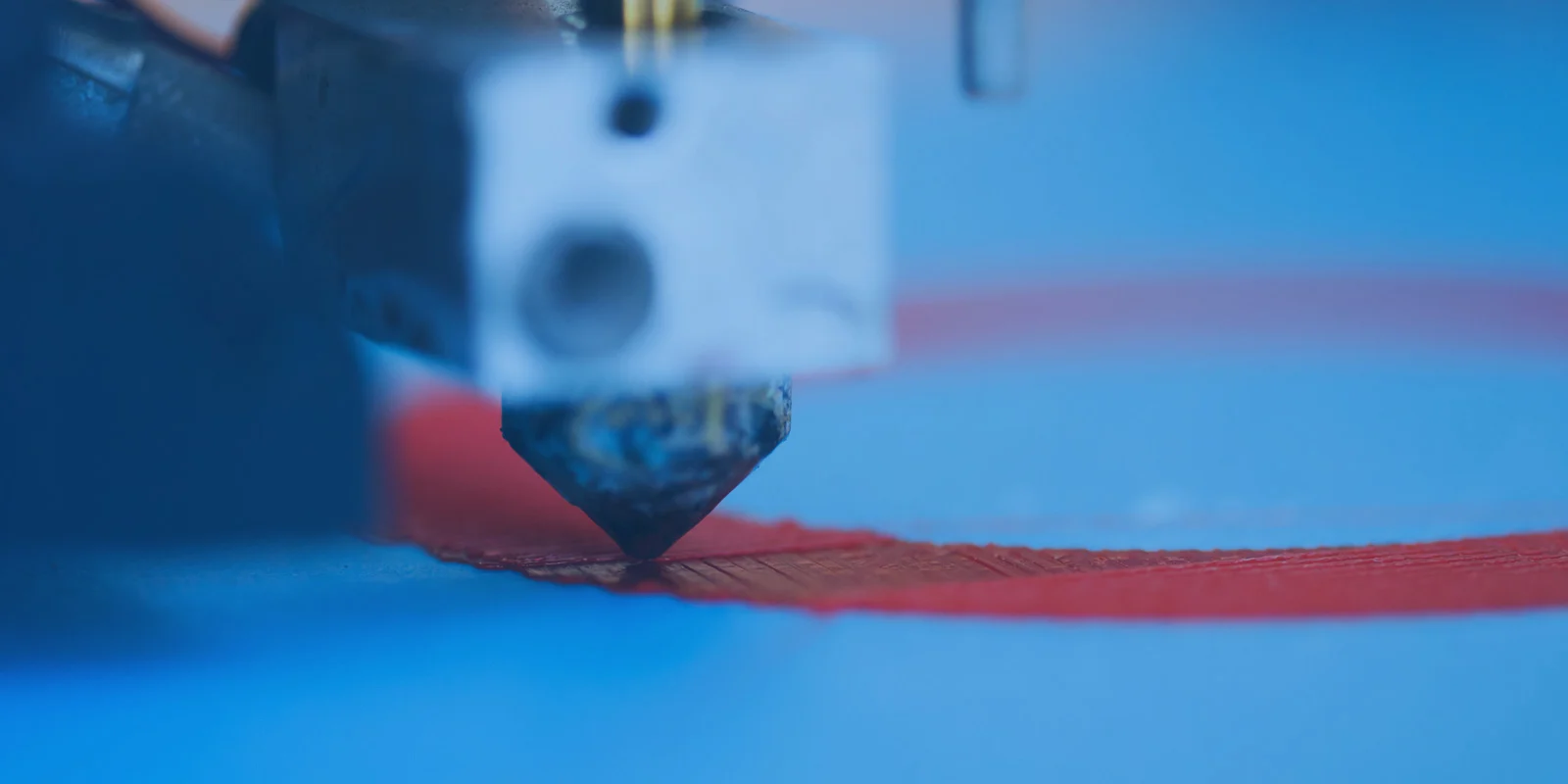

3D Printing

3D printing allows you to turn your ideas into real, three-dimensional objects. Create or download 3D models, then submit a request for printing with our 3D printer—a LulzBot TAZ Pro with dual extrusion—in colorful PLA filament.

Interested in learning more? Email [email protected] with your questions.

Submit a 3D print request

3D printing services are available to SWAN library cardholders in good standing.

Submission guidelines

In order to get you the best prints as quickly as possible, we ask that you adhere to these guidelines when submitting files. Files must be print-ready; to ensure the accuracy of all prints, staff will not make modifications to models.

- Format: STL (STL files can be exported from from Tinkercad, Meshmixer, and many other modeling apps.)

- Maximum dimensions: 298 mm x 275 mm x 250 mm (11.7 in x 10.8 in x 9.8 in) — All models should be submitted at actual print size. We will not resize models.

- Maximum print time: 6 hours

- User Agreement: All submissions will be reviewed by staff and must follow the Makery 3D Printer User Agreement. If this is your first print request, please submit a signed copy of the agreement beforehand or include it with your request.

What we need to know

When requesting a 3D print, include the following information with your file:

- Name and library card number

- Print dimensions

- Color(s) — Please see our list of currently available colors. The TAZ Pro can print in two colors; see the tutorials below for instructions on preparing two-color models.

- Brim | no brim — A brim is a single-layer of material added around the perimeter of the model’s base to increase stability during printing. Brims are generally easy to remove but may leave a small amount of material on the bottom edge.

- Supports | no supports — Supports are added wherever the printer software detects overhangs and may cover a substantial portion of the model. These supports add a negligible amount of material, which may increase printing cost. We cannot show you a preview of the automatically generated supports.

Files may be submitted by email (up to a maximum of 25 MB) or in person.

Submissions will be handled in the order in which they are received, with priority given to Library programs. Staff will contact you when your model is ready to pick up.

Cost

Prints are priced at $0.10/g. To determine how much your model will cost, find the estimated mass of your print:

- Open your STL file in Cura.

- Select PLA as the material and choose Normal print quality.

- Cura will calculate the mass of your model in grams and display this in the upper left, which will allow you to estimate price.

After you submit a file, a staff member will review the model. We will contact you to confirm the price before printing.

Questions?

Contact the Makery staff at [email protected].

Software & other resources

Anyone can learn 3d design. There are projects and software for all skill levels. Free programs for modeling include:

- Tinkercad — Make models in your browser with simple CAD tools and save them online.

- Zbrushcoremini — Sculpt a ball of virtual clay using intuitive tools.

- Meshmixer — Remix existing models, sculpt, stamp, and texturize.

Our TAZ Pro printer is capable of dual extrusion, which allows for two-color prints. Basic instructions for creating two-color models using Tinkercad can be found in these tutorials: Tutorial 1 | Tutorial 2

Other sources for printable 3D models — Download objects made by other creators and share your own on these sites:

Thingiverse | YouMagine | My Mini Factory | Thangs | Printables

From our Digital Branch

Udemy

Improve your skills and explore new interests with Gale Presents: Udemy, an online learning platform offering on-demand, professionally-taught video courses in business, technology, design, and more.